For half of the world, November means colder weather. It means bundling up - big sweaters, hats, scarves, and down jackets. Whether you’re outside for work, play, or just to get to your next destination, down has been the insulation of choice for ages. It’s also an incredibly important material in the outdoor gear you rely on to push your seasons in the outdoors - sleeping bags, pads, and big puffy jackets enable you to go further, stay out longer, and to be more comfortable while doing it. But not all down is created equal - the quality plays a big role in the weight, packability, durability, and warmth. We’re going to take a look at the science that makes all this possible, and how you can wade through all the technical jargon to find the gear that will get the job done.

How does it work?

Despite what you may think, down filling is not made from feathers. It’s made from goose or duck plumage, the fluffy insulation directly under the feathers. This is nature’s mid-layer, and despite our best efforts in science, we’ve still not made a more effective insulator for these applications. In use, down’s clusters are three-dimensional structures with thousands of filaments that criss-cross to create air space. Just as a sponge traps water, down clusters trap warm air while still allowing moisture and air to move through.

Down Quality

Down quality is measured by it’s ‘fill power’, or ‘loft’, which in simple terms is a measure of the down cluster’s size. Larger clusters trap more air and are both warmer and lighter when compared to lower quality down. The larger the down cluster, the higher the fill power rating is. Fill power represents how many cubic inches one ounce of down will occupy. If one ounce of down takes up 700 cubic inches of space, it is rated as 700-fill-power down - and signifies that less will be needed to achieve the same warmth as a 600-fill-power or lower quality down. In effect, you can achieve the same warmth rating with less down, so you have a lighter product. In general, there are 3 different grades of down often used: 550-650-fill downs are high quality down, 650-750-fill down is a performance down, and the 750-900 fill downs are premium downs - the lightest, warmest, and most expensive.

DWR Treated Down

One of the great downfalls of down is that it does not insulate well when wet. Those down clusters compress, and it can no longer trap air between its fine fibers. When down is first harvested from a duck or goose, it is water repellant - natural oils on the plumage make water fall away and it keeps insulating. When down is processed and washed, some of these oils are removed. There have also been improvements in washing methods, which remove less of these natural water repellant oils, but generally, DWR treatments are used to restore down’s natural ability repel water. There are several on the market right now, including the HyperDRY down that we use in our products. This is a durable, fluorocarbon-free, water-resistant down made possible by a natural wax-based compound.

Responsibility

It has become important to consumers and producers that down is responsibly sourced - meaning it does not come from animals that were subject to unnecessary harm. This includes standards that say down can not be live plucked from birds, that birds cannot be force fed, and that producers have “holistic respect for animal welfare” throughout their lives. The Responsible Down Standard has become the worldwide certification for ensuring down is responsibly sourced. Zenbivy is proud to be RDS compliant, and all of the down used in our products can be traced back to its source.

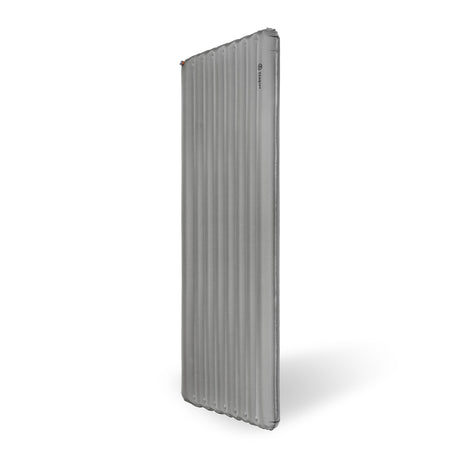

Our Zenbivy Light Beds use some of the highest quality 800-fill-power HyperDRY down to reduce weight while not sacrificing warmth. We use 700-fill-power HyperDry down in our Original Zenbivy Beds where comfort is more important than weight.